Plywood Formwork Panels

Plywood for Concrete Formwork

Concrete Shuttering Panels

Nationwide delivery of packs and commercial volumes to trade customers

For details and prices:

Plywood overlaid with a smooth coating for concrete formwork or shuttering

We offer dark brown smooth phenol, MDO (medium density overlay) or polypropylene faced panels

Edges sealed in water-proof paint to prevent moisture ingress

Cut to size service for replacement panels for popular formwork systems

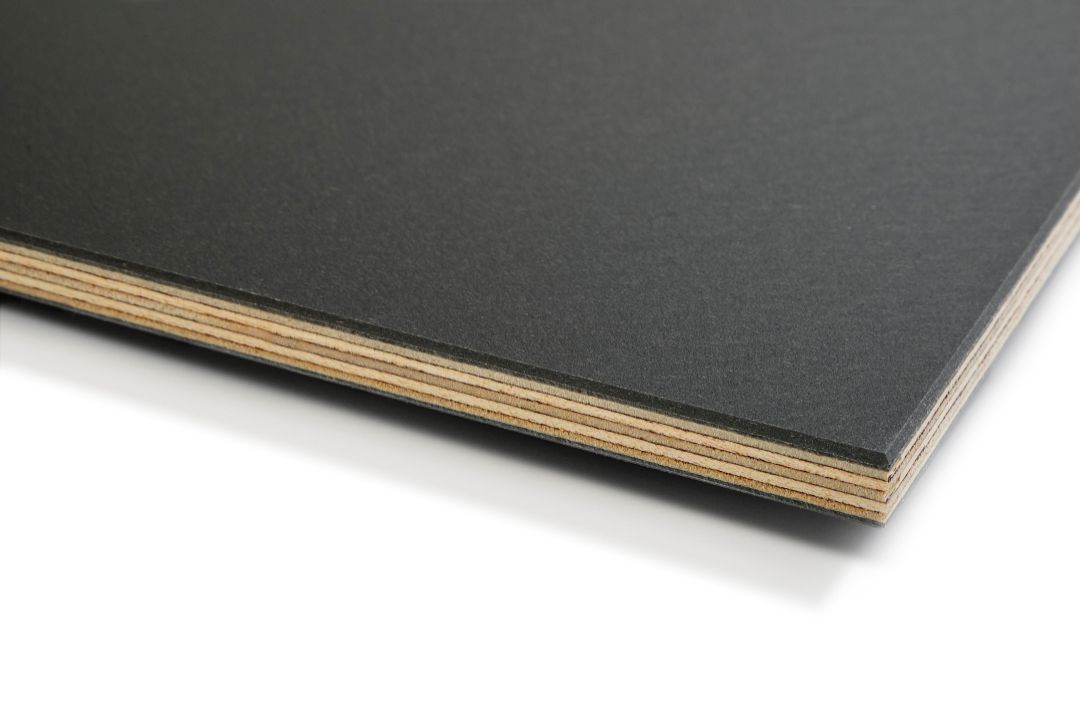

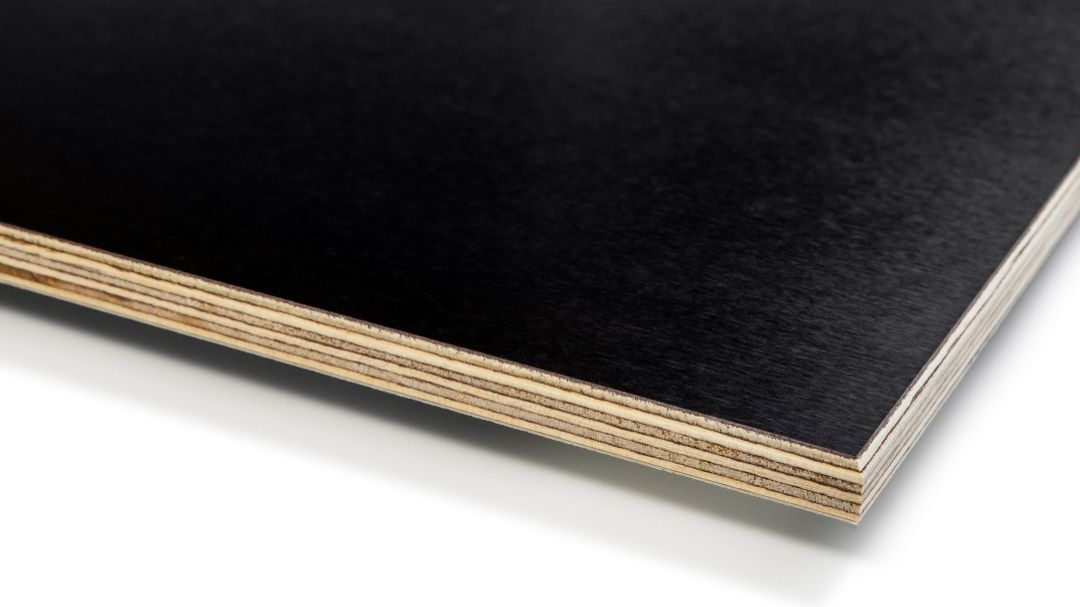

Phenol Faced Birch Plywood

Birch throughout plywood core, exterior glue bonded, edges sealed

The smooth phenol surface is smooth, glossy and hard. It resists abrasion, it is weather and moisture proof and resists commonly used chemicals, dilute acids and alkalis. The surface is easy to clean with water or steam. Can be re-used many times.

Panel Sizes

The majority of our customers take cut to size panels. We have UK facilities for quick cutting, or can offer cut panels directly from the mill.

Below are full size panels that can be offered, with 1220 x 2440 being the standard stock item we hold.

Standard Press

| Metric | Imperial |

|---|---|

| 2440 x 1220 | 8ft x 4ft |

| 1220 x 2440 | 4ft x 8ft |

| 1525 x 1220 | 5ft x 4ft |

| 1525 x 1270 | |

| 1525 x 1525 | 5ft x 5ft |

| 1525 x 3050 | 5ft x 10ft |

| 1250 x 2500 | |

| 2500 x 1250 |

Large Standard

| Metric | Imperial |

|---|---|

| 1220 x 2745 | 4ft x 9ft |

| 1220 x 3050 | 4ft x 10ft |

| 1220 x 3340 | 4ft x 11ft |

| 1220 x 3660 | 4ft x 12ft |

| 1500 x 2500 | |

| 1500 x 3000 | |

| 1525 x 2745 | 5ft x 9ft |

| 1525 x 3660 | 5ft x 12ft |

Extra Large Press

| Metric | Imperial |

|---|---|

| 1830 x 3050 | 6ft x 10ft |

| 1830 x 3340 | 6ft x 11ft |

| 1830 x 3660 | 6ft x 12ft |

| 1830 x 3850 | 6ft x 12ft 6" |

| 2150 x 3050 | 7ft x 10ft |

| 2150 x 3340 | 7ft x 11ft |

| 2150 x 3850 | 7ft x 12ft 6" |

| 2150 x 4000 | |

| 2290 x 4000 |

Specifications

Thickness

9mm / 12mm / 15mm / 18mm / 21mm

Other thickness on request

6.5mm / 15mm / 24mm / 27mm / 30mm / 35mm / 40mm

Faces

Phenol Overlay

Dark brown as standard

Paper impregnated with phenol resin

Moisture and chemical resistant. Does not crack.

Available in 120g, 220g and 240g

Pack Size

9mm 44 sheets

12mm 33 sheets

18mm 22 sheets

21mm 19 sheets

Core Construction

Standard birch plywood multi-laminated construction

Internal veneers: 1.4mm thick birch throughout

Weight

680kg per M3*

*approximate and subject to natural variation

Bonding

EN314-2 class 3 - dark brown glue, exterior conditions

(previously WBP: Weather and Boil Proof)

Edges

Edge sealed with exterior acrylic paint to prevent moisture ingress

To match phenol face colour

Formaldehyde

In accordance with the standard EN 13986

Formaldehyde emission meets the Class E1 requirements

(test method EN 717 Part 2)

MDO Plywood

Medium Density Overlay Boards

MDO gives a matt surface finish to the struck concrete and minimises grain pattern transfer

Spruce MDO is light weight and easy to handle on site

Known as Wisa-Form MDO panels

Specifications

Thickness & Panel Size

18mm 2440 x 1220

Faces

MDO Overlay: Resin impregnated craft paper. Must be oiled twice prior to first use and once before every other use.

Reverse: Dark brown phenolic film balancer

Pack Size

18mm 50 sheets

Core Construction

Standard spruce plywood multi-laminated construction

Weight

450kg per M3*

*approximate and subject to natural variation

Bonding

EN314-2 class 3 - dark brown glue, exterior conditions

(previously WBP: Weather and Boil Proof)

Edges

Edge sealed with light brown water resistant paint

Formaldehyde

In accordance with the standard EN 13986

Formaldehyde emission meets the Class E1 requirements

(test method EN 717 Part 2)

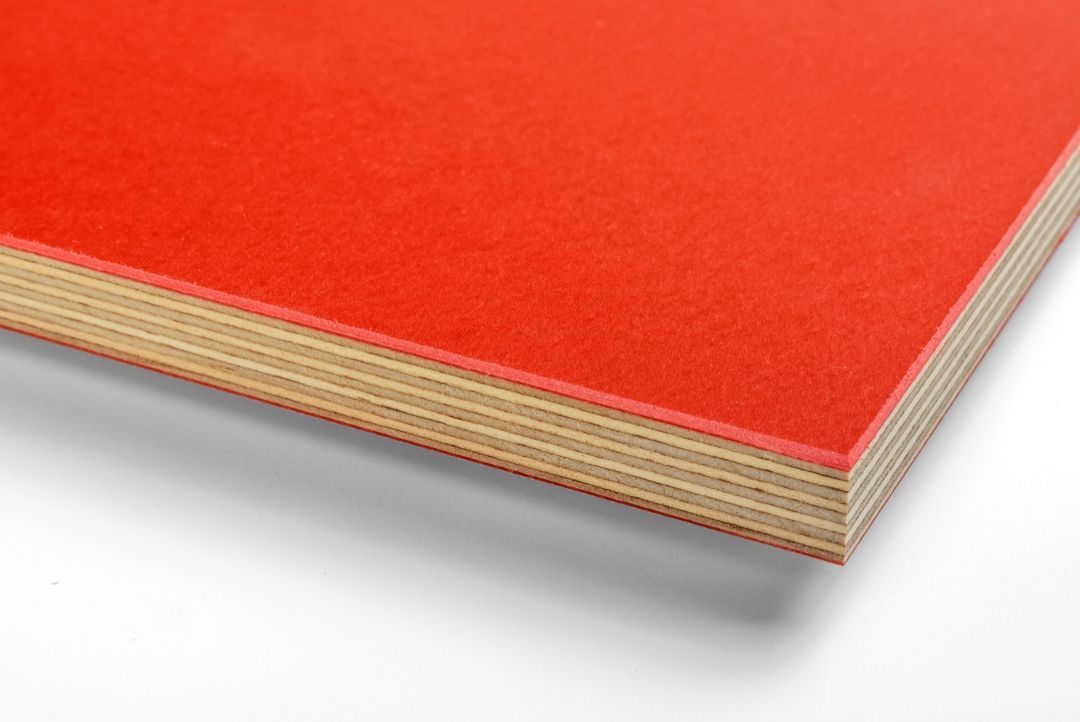

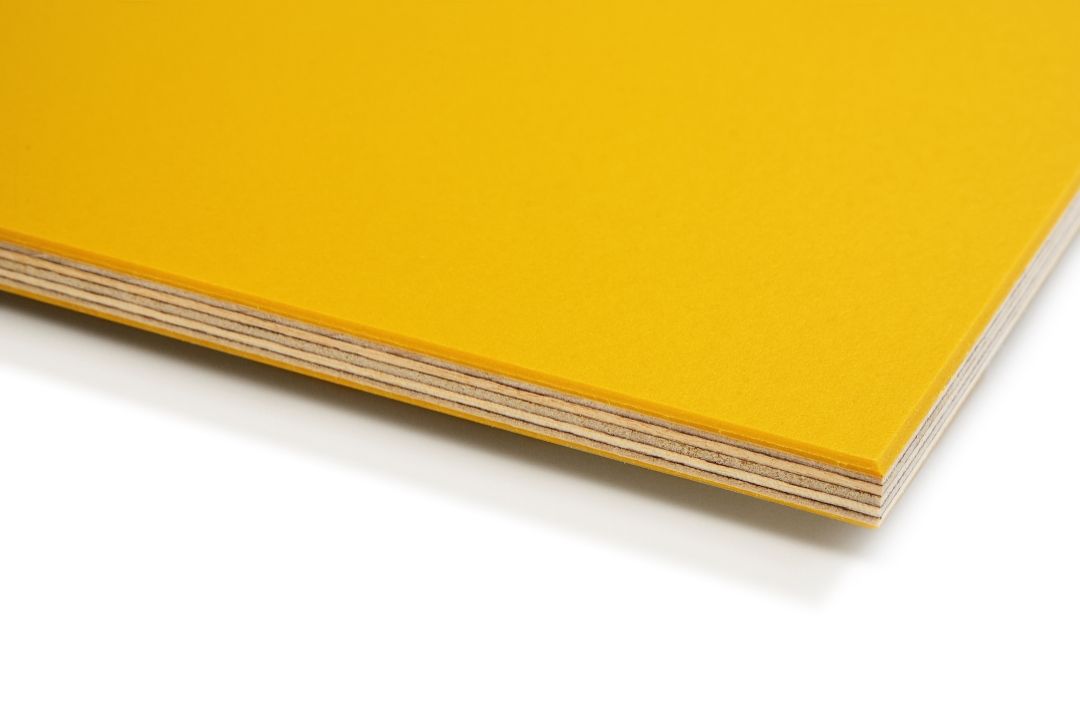

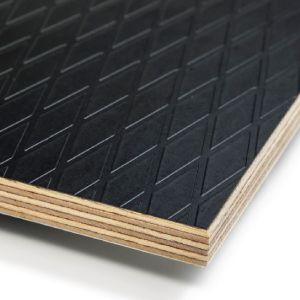

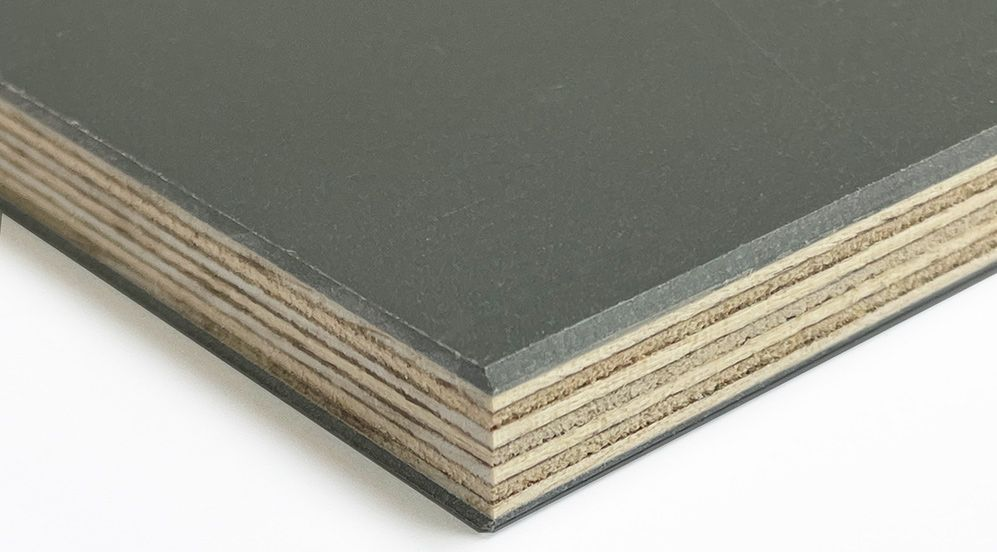

Poliform Plywood

Riga Poliform - Birch plywood core overlaid on both faces with a special composite material, that is ecologically safe and recyclable.

Produces a superior appearance to the concrete surface and when properly used the manufacturer estimates up to 300 uses when correctly installed. Heavy duty formwork plywood.

- Tough and impact resistant surface for smooth concrete finish

- No rippling

- As many as 300 reuses when correctly installed

- Recycled wood fibres utilised in the wood-plastic overlay

- Water resistant surface and weather resistant gluing

- Surface is resistant to commonly used concrete release agents, diluted acids and alkalis, easy to clean with water or steam for repeated uses

- Special solutions are available for applications requiring a higher surface elasticity such as nailing

- Easy to machine and fix on site

- Variety of standard sizes, cut-to-size and jointed panels available

- Sustainable product with long life-span

- The wood-plastic composite coating offers a highly durable, hard and dense surface, increasing panel resistance against mechanical damage and wearing.

- It resists concrete release agents, cement alkalis and other corrosive chemicals.

- The panels can be used within a temperature range from −40 °C up to +80 °C.

- Cold temperatures can reduce WPC flexibility making it less suitable for nailing.

- After use, panels release well and maintain their performance for a long time.

- Surface hardness (Shore D Durometer) for WPC SP >72 HD; WPC SP2 >62 HD

- Taber test (EN 438-2) up to 17,000 revolutions

Specifications

Thickness

Standard thickness: 18mm

Special order: 9mm / 12mm / 15mm / 21mm / 24mm

Faces

1.6mm thick composite of wood fibres and polypropylene. It resists various kinds of damage, will release well and maintains a long performance life. Bonded with C4 class glues according to EN 12765. UV resistance is average to good.

Panel Sizes

1220 x 3050

1250 x 2500 / 3000 / 3340 / 3660

1500 x 2500 / 3000

1525 x 2440 / 3050 / 3340 / 3660

Core Construction

Standard birch plywood multi-laminated construction

Internal veneers: 1.4mm thick birch throughout

Weight

680kg per M3*

*approximate and subject to natural variation

Bonding

EN314-2 class 3 - dark brown glue, exterior conditions

(previously WBP: Weather and Boil Proof)

Edges

Exterior acrylic paint to prevent moisture ingress

To match face colour

Formaldehyde

In accordance with the standard EN 13986

Formaldehyde emission meets the Class E1 requirements

(test method EN 717 Part 2)

Poliform Colours

Not offered as a decorative panel

Colours are for site identification purposes or corporate branding considerations

Cutting Service

Cut to size formwork panels & CNC machined formwork panels

We offer a full cutting and processing service

Router, drill, chamfer or machining

Edges are sealed with external paint

For more information on our cutting & machining services

Allow approx. 15 working days for our cut to size service, depending on volumes and complexity

We stock a wide range of standard and specialist formwork and shuttering panels. For non standard requirements we are able to cut, machine and edge seal in the UK from our grounded stock or provide forward shipments direct from the mill.

We can offer the panel you require to suit your budget and the required concrete finish. Raw panels for standard work or overlaid panels for high quality projects. We supply a range of panels and components to recognised industry names.

Data sheets and strength tables are available. Contact us for more information.

Other Coated Panels

Our range of overlaid birch plywood panels