Plywood Rebound Boards

Birch Plywood

Rebound Boards

Five-a-Side Pitches

MUGA Fence Panels

Supplying rebound panels to fencing contractors with nationwide delivery

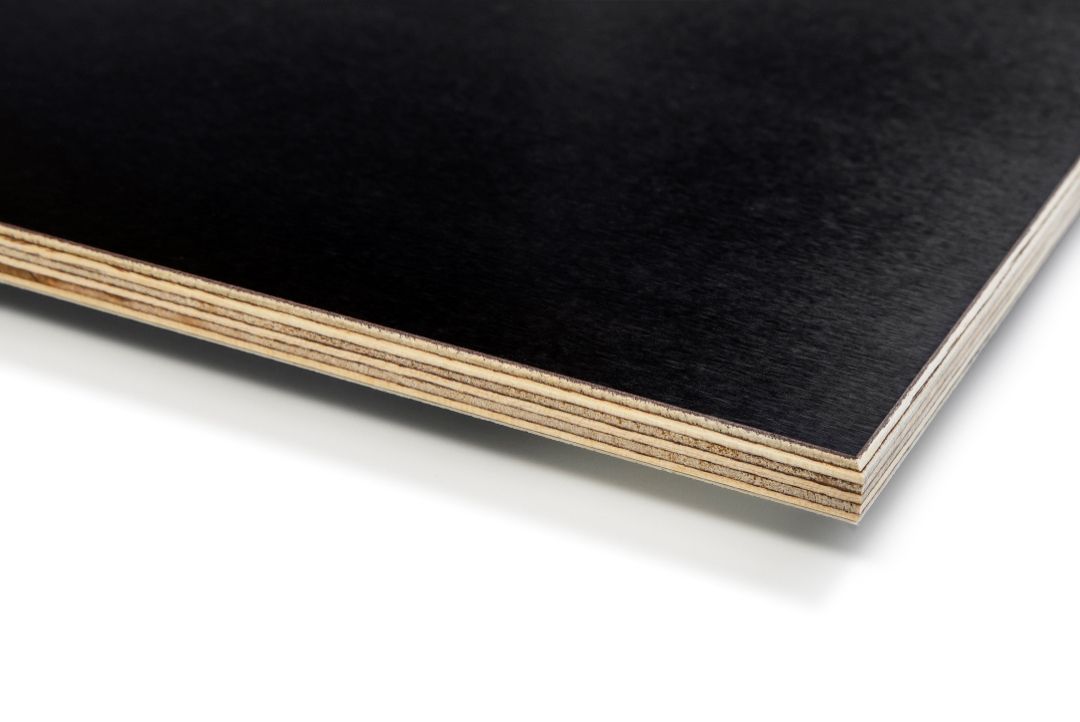

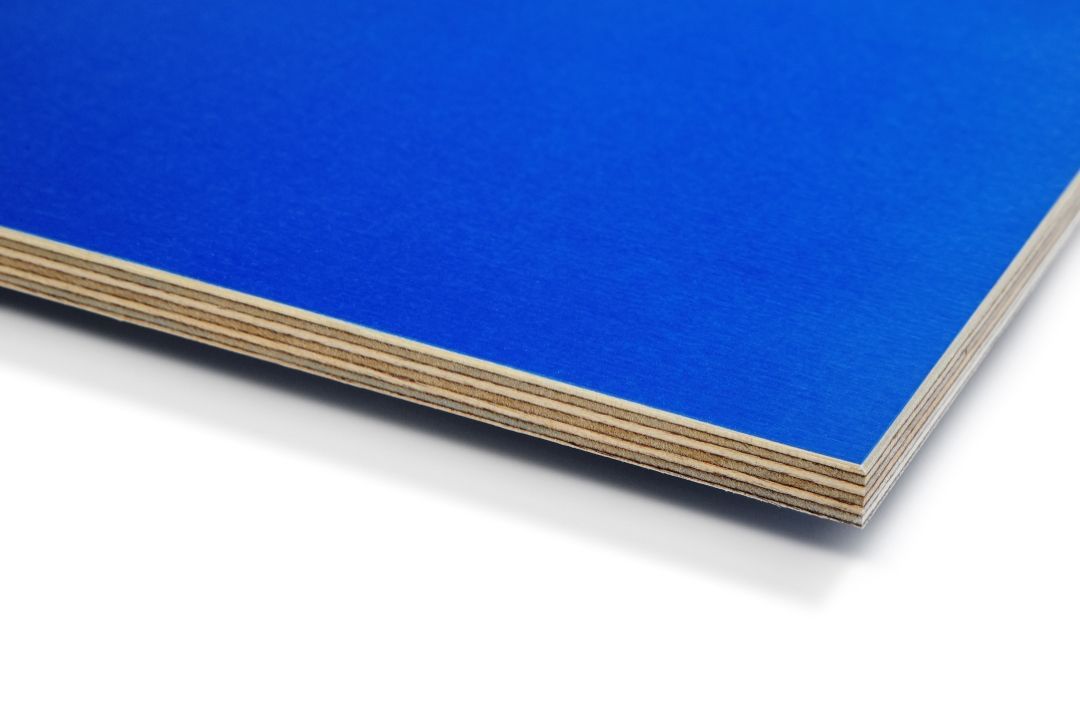

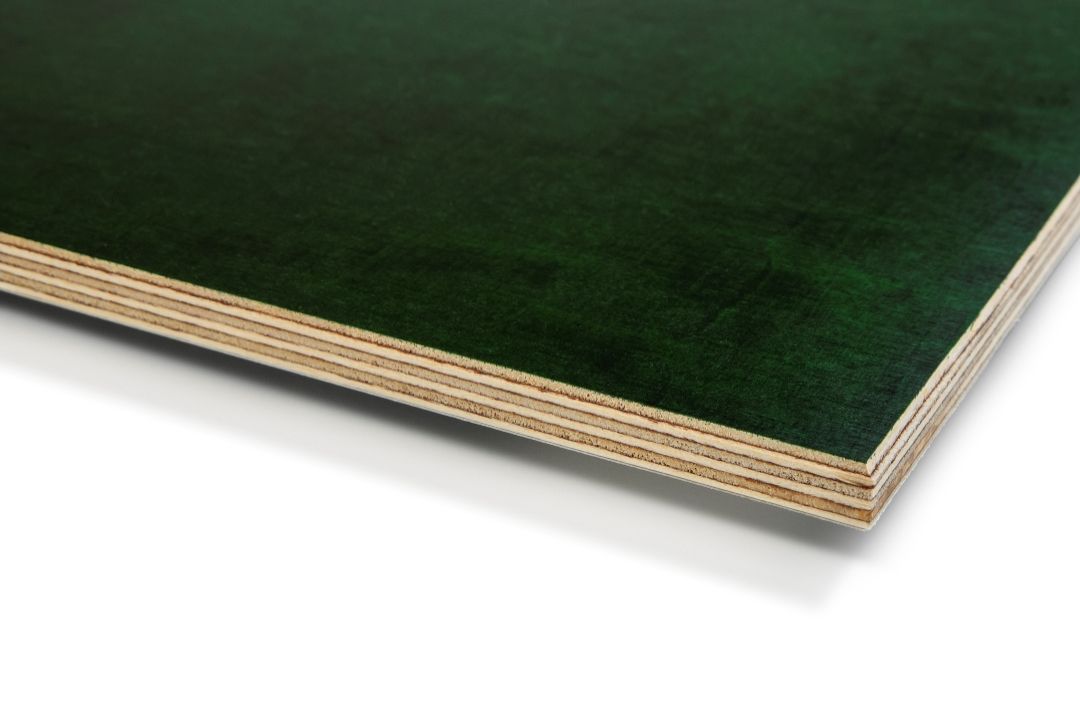

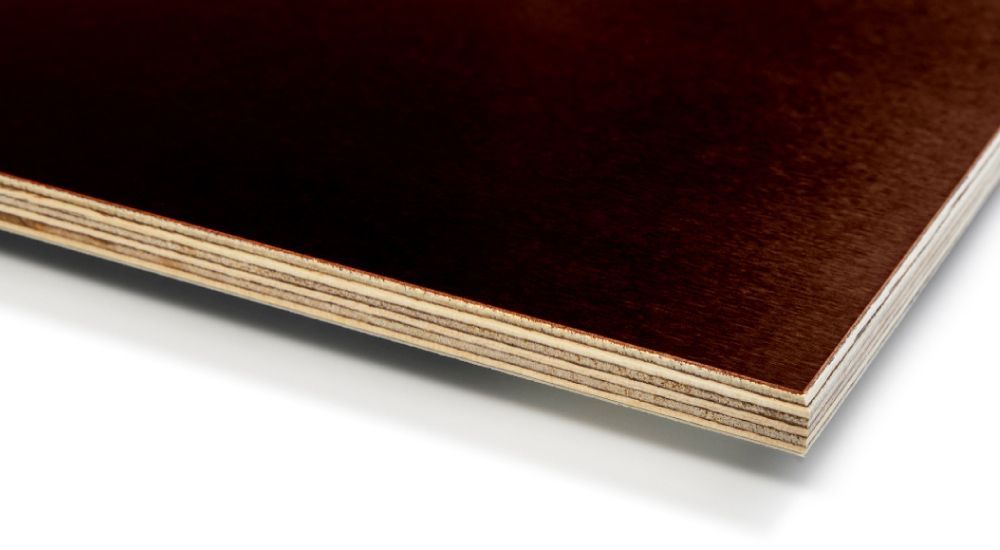

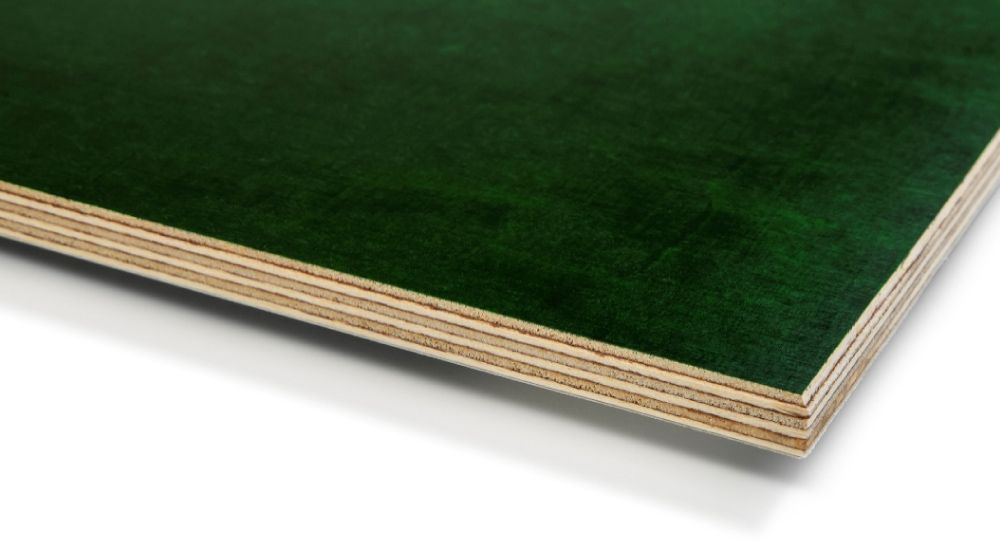

Phenol Faced Birch Plywood

Smooth phenol overlay bonded to birch plywood

Suitable for outside sports rebound panels

Resists impact and abrasion

Low maintenance, easy clean surface with water or steam

Weather resistant glue line and water resistant finish

Colours

Phenolic Resin:

Dark Brown - Light Brown - Black - Green - Yellow

Melamine Resin:

Silver Grey - Light Grey - Honey Brown - Blue

Film weights available from 120g/m² to 440g/m²

Phenol film is not UV fast and the colour will change over time

Specifications

Thickness

12mm / 15mm / 18mm

Other thickness on request

Panel Sizes

2440 x 1220 (8ft x 4ft)

1200 x 2990 / 3000

1220 x 2990 / 3000 / 3050

1250 x 2500 / 2990 / 3000 / 3340 / 3660

1500 x 2500 / 2990 / 3000

1525 x 2440 / 2990 / 3050 / 3340 / 3660

Other sizes on request

Phenol Overlay

Available in a range of colours

Paper impregnated with either phenol or melamine resin

Moisture and chemical resistant

Available in 120g, 220g, 240g, 440g

Minor visual defects (rippling, blemishes, overlaps, scratches) are permitted in the grading rules

Core Construction

Standard birch plywood multi-laminated construction

Internal veneers: 1.4mm thick birch throughout

Edge Sealing

Edge sealed with exterior acrylic paint

To compliment phenol face colour

Triple edge seal as standard

Bullnosed edges: on request

Bonding Quality

EN314-3 class 3 exterior conditions

Dark brown glue-line, phenol resin

Weight

640-700 kg/m³

12mm 8x4 weighs approx. 25kg

18mm 8x4 weighs approx. 37kg

Formaldehyde

In accordance with the standard EN 13986

the formaldehyde emission meets the Class E1 requirements

(test method EN 717 Part 2)

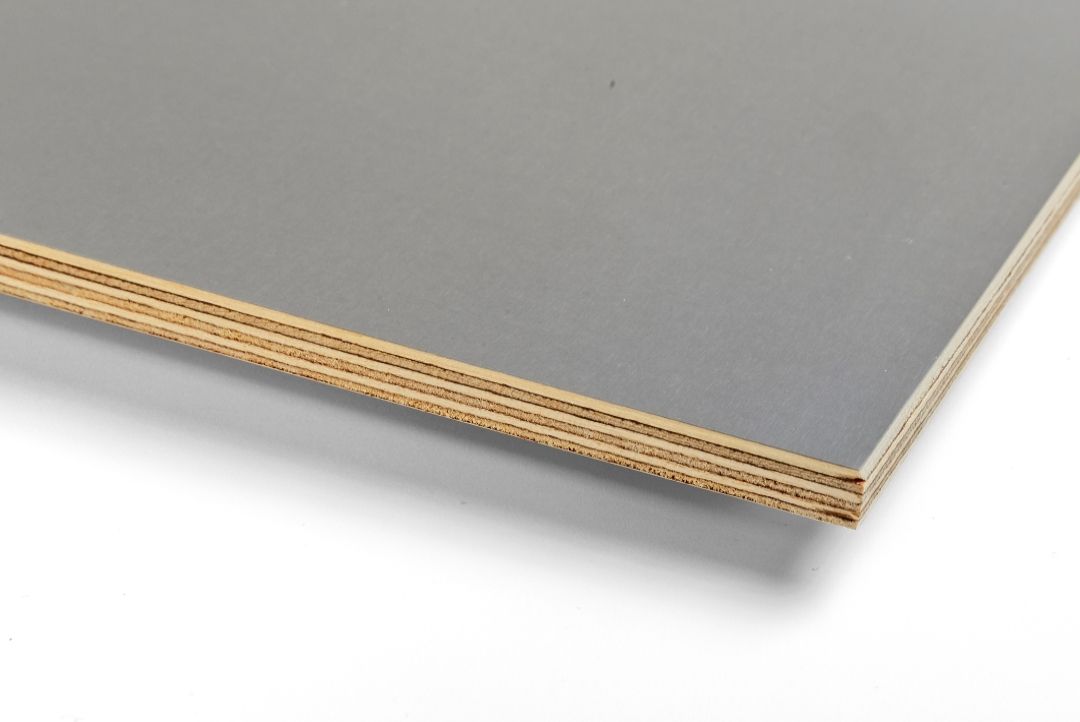

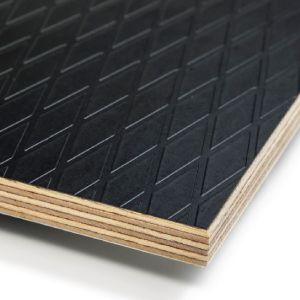

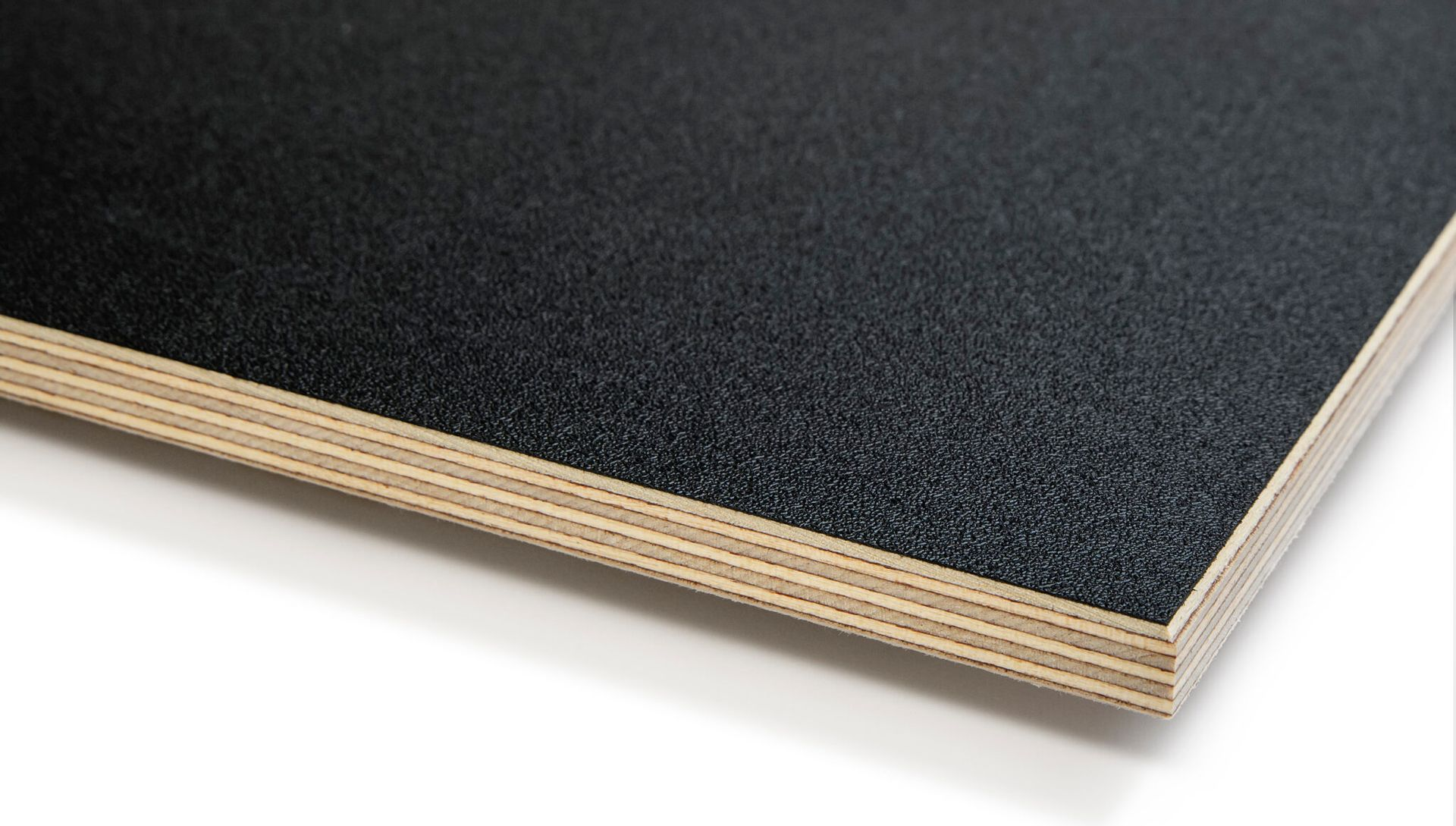

Polypropylene Faced Birch Plywood

Textured polypropylene (PPL) overlay suitable for outdoor sports pitch perimeters

Available in white, black or grey

UV resistant faces for both indoor and outdoor use

Specifications

Thickness

Core: 12mm / 15mm / 18mm

With 0.65mm overlay on both faces:

13.3mm / 16.3mm / 19.3mm

Other thickness on request

Panel Sizes

2440 x 1220 (8ft x 4ft)

1200 x 2990 / 3000

1220 x 2990 / 3000 / 3050

1250 x 2500 / 2990 / 3000 / 3340 / 3660

1500 x 2500 / 2990 / 3000

1525 x 2440 / 2990 / 3050 / 3340 / 3660

Other sizes on request

PPL Overlay

Available in white (RAL 9016), black (RAL 9005) or grey (RAL 7045)

Improved impact and crack resistant faces

Durable, wear and UV resistant

Textured 0.65mm thick overlay pressed to both faces

Core Construction

Standard birch plywood multi-laminated construction

Internal veneers: 1.4mm thick birch throughout

Edge Sealing

Edge sealed with exterior acrylic paint

To compliment PPL face colour

Triple edge seal as standard

Bullnosed edges: on request

Bonding Quality

EN314-3 class 3 exterior conditions

Dark brown glue-line, phenol resin

Weight

640-700 kg/m³

12mm 8x4 weighs approx. 25kg

18mm 8x4 weighs approx. 37kg

Formaldehyde

In accordance with the standard EN 13986

the formaldehyde emission meets the Class E1 requirements

(test method EN 717 Part 2)

Handling, Storage & Installation

Prior to installation panels must be stored:

- On a level surface: flat, horizontal, un-banded and on the pallet base they are supplied with

- In a well ventilated, weather protected environment with stable humidity

Installation Guidance:

Allow a 3-4mm expansion gap between panels:

- to accommodate natural expansion during the wetter months

- to help prevent warping and bowing

- to avoid creating pressure on fixings

- to allow edges to dry quicker after wet weather

- Use strong stainless steel fixings that are suitable for exterior conditions

- Any edges cut on site must be re-sealed with an exterior paint

- Any damage / breeches to the overlay during installation must be sealed

- To prevent swelling and damage, panels should not be in direct contact with the ground. If using metal channels ensure and maintain proper drainage.

Regular maintenance to extend panel life:

- Any damaged or exposed edges and faces must be carefully re-sealed

- Organic debris should not be allowed to build up against the base of the panels. This prevents prolonged periods of contact with moisture.

Other Coated Panels

Our range of overlaid birch plywood panels