Veneered Plywood

Appearance

Veneered Plywood Appearance

Face Grades

Every panel requires both sides to be veneered and the grade of each to be specified

If the reverse is not intended to be seen, then a low grade random veneer will be applied

This is referred to as a "balancer" or "balancing veneer". It equalises the panel tension and improves dimensional stability. Without a balancer, the panel will be prone to warping.

A Grade

B Grade

Balancer

Top grade for high end decorative use

This would be the front facing side

A lower grade veneer

Usually the same species as the face

Occasionally seen - i.e. inside of cupboards

Low grade veneer of a random species

Species can vary within the same manufacture run

Never intended to be seen

Natural

Select

Sequenced

Varied & irregular with greater colour variation

A shorter series of similar faces

Our standard quality

Good structure with small variation in colour

Generally attractive appearance

Premium quality

Similar consistency of colour and structure

A minimum of 8 boards from the same log

Every panel requires both sides to be veneered and the grade of each to be specified. If the reverse is not intended to be seen, then a low grade random veneer will be applied. This is referred to as a "balancer" or "balancing veneer". It equalises the panel tension and improves dimensional stability. Without a balancer, the panel will be prone to warping.

A Grade

Balancer

B Grade

- Top grade for high end decorative use

- This would be the front facing side

- A lower grade veneer

- Usually the same species as the face

- Occasionally seen - i.e. inside of cupboards

- Low grade veneer of a random species

- Species can vary within the same manufacture run

- Never intended to be seen

A Grade

Balancer

B Grade

- Top grade for high end decorative use

- This would be the front facing side

- A lower grade veneer

- Usually the same species as the face

- Occasionally seen - i.e. inside of cupboards

- Low grade veneer of a random species

- Species can vary within the same manufacture run

- Never intended to be seen

Veneer Selection

Natural

Sequenced

Select

- Varied & irregular with greater colour variation

- A shorter series of similar faces

- Our standard quality

- Good structure with small variation in colour

- Generally attractive appearance

- Premium quality

- Similar consistency of colour and structure

- A minimum of 8 boards from the same log

Natural

Sequenced

Select

- Varied & irregular with greater colour variation

- A shorter series of similar faces

- Our standard quality

- Good structure with small variation in colour

- Generally attractive appearance

- Premium quality

- Similar consistency of colour and structure

- A minimum of 8 boards from the same log

Long-grain or cross-grain available on most veneers

Appearance

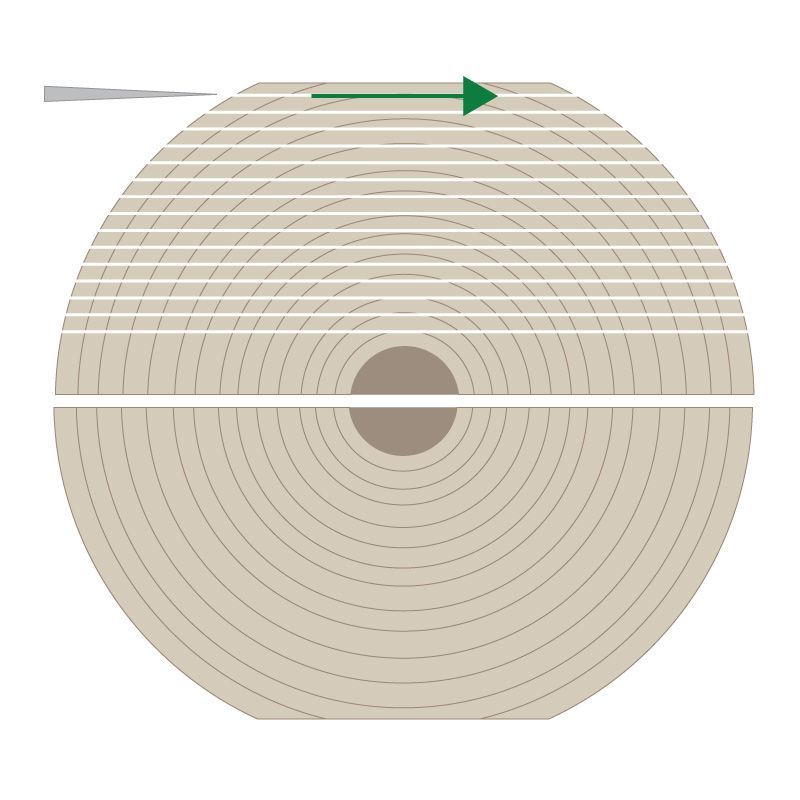

There are various cutting methods that result in different appearances

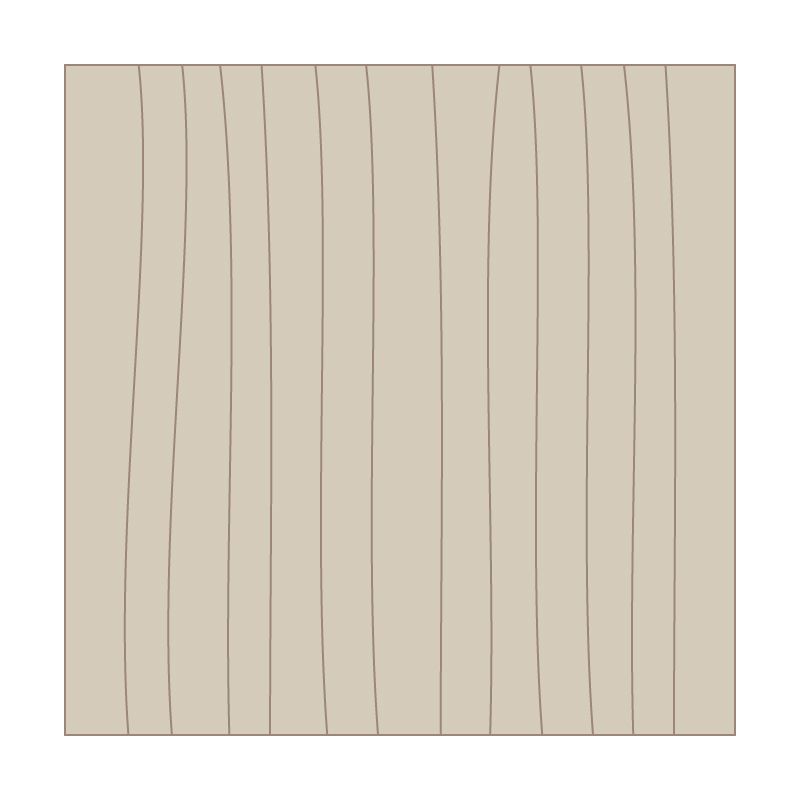

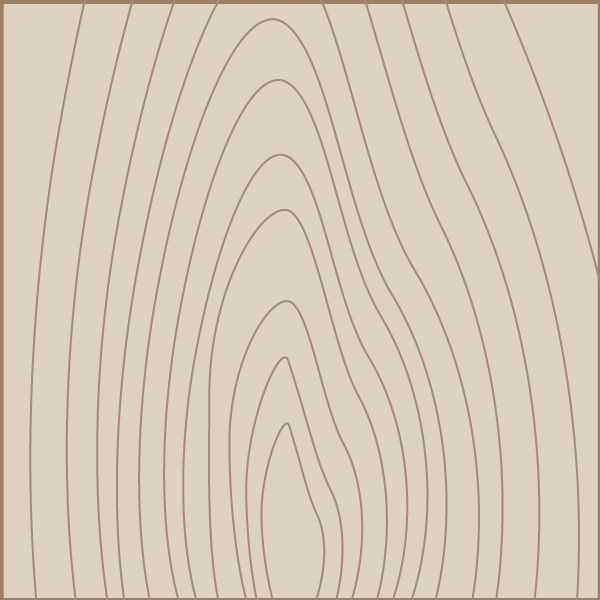

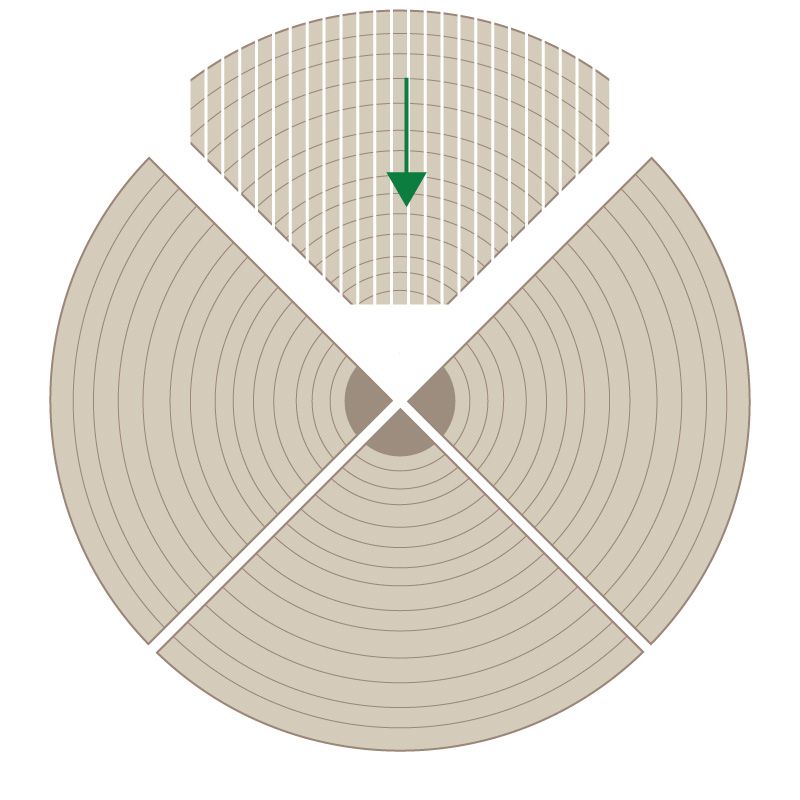

Crown Cut

The log is first cut in half then sliced straight across the growth rings.

Characteristic elliptical rings known as cathedrals are present in the centre with straighter grain at each edge.

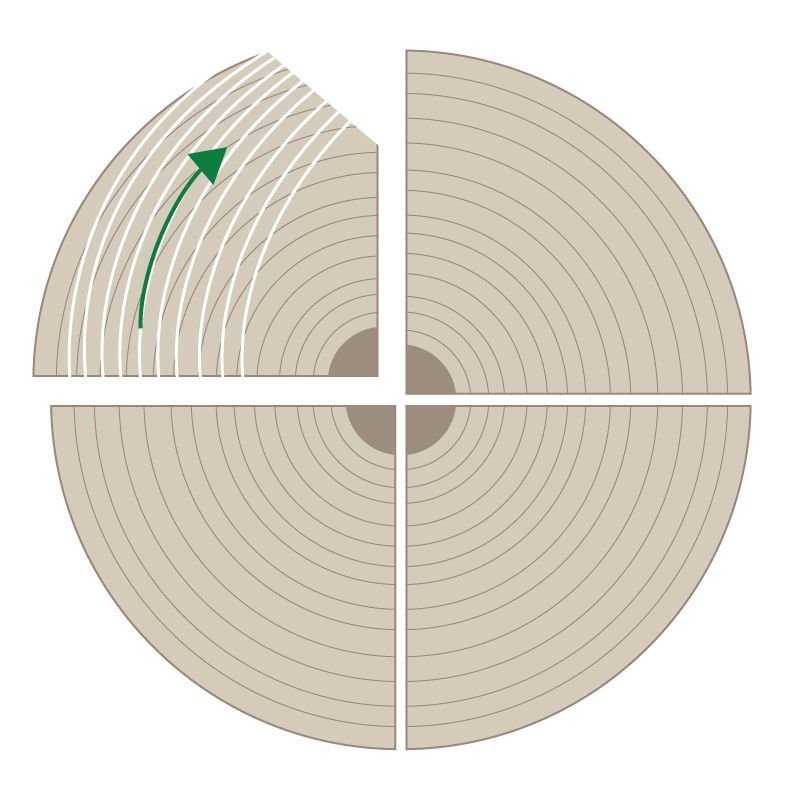

Quarter Cut

The log is first quarter cut then each flitch is straight sliced at right angles to the growth rings.

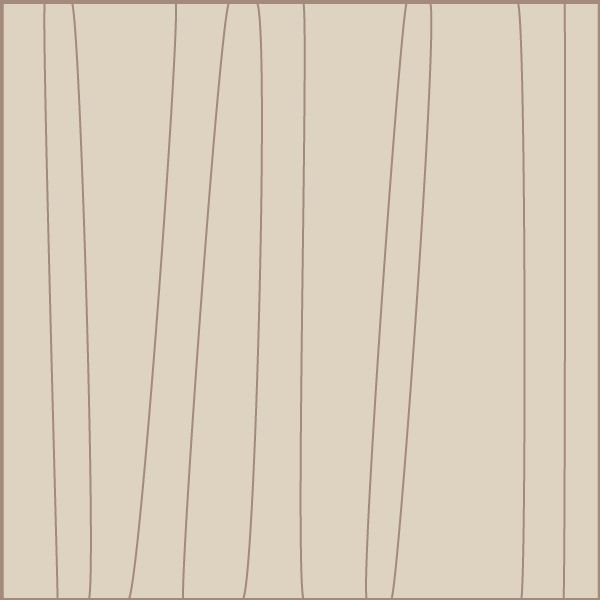

A straight, uniform and linear grain is produced.

Rift Cut

The log is quarter cut then lathe mounted. Curved slices are peeled slightly across the rings. This accentuates the vertical grain.

Popular in Oak veneer as this enhances the medullary rays.

Uniformity

Each veneer layon will show variation in grain pattern and colour tone.

Also present will be other natural characteristics inherent in real wood.

If a more uniform appearance is required, to mitigate this natural variation we can offer:

Option 1

Sequential matching

Each panel is laid from a single log

Option 2

Project matching

A labour-intensive service where layons are sorted through to find similar profiles.

Contact us to discuss your requirements

Veneer Thickness

By default, veneers are peeled 0.5mm to 0.6mm thick

Up to 1.5mm thickness is available for some species

Veneer Matching

Unless otherwise specified...

Crown cut layons will be supplied book matched

Quarter cut layons will be supplied slip matched

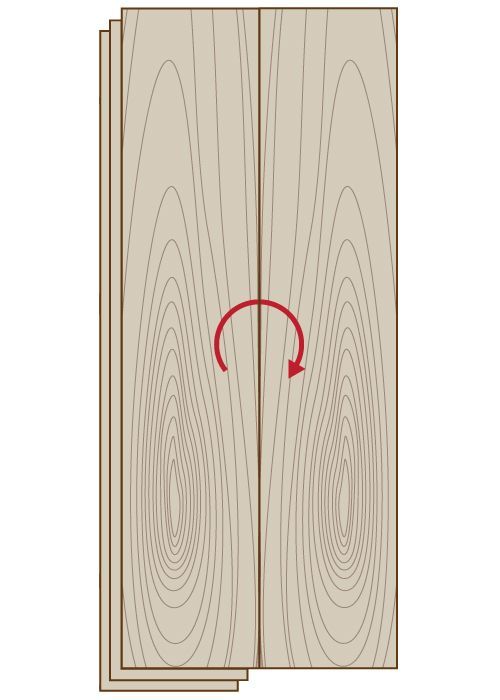

Book Matched Veneer

Veneers are opened like a book and joined

producing a symmetrical mirrored effect

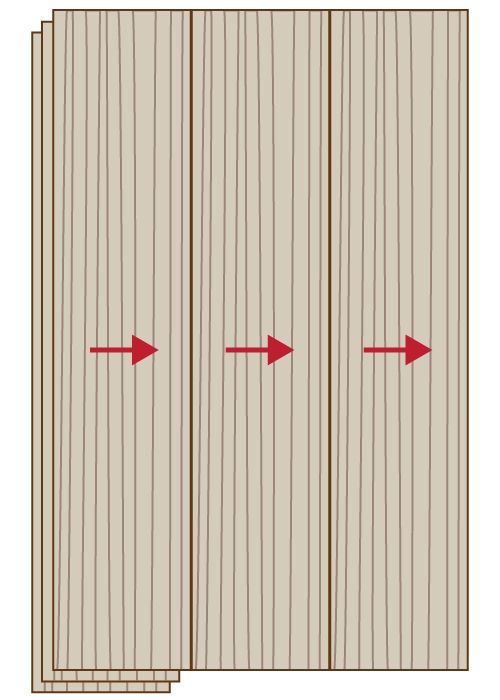

Slip Matched Veneer

Consecutive veneers are joined

without turning over the leaves

creating a repeating pattern

Other matching options are available:

Book & Turn Matching

As book matching, but alternate leaves are turned so the grain is in the opposite direction

Slip & Turn Matching

As slip matching, but alternate leaves are turned so the grain is in the opposite direction.

Quarter Matching

Four veneer strips are book matched from side to side and top to bottom. Used for creating larger veneer panels.

Random Matching

Mixes veneers not necessarily from the same log, with some turned to create a random effect on the grain pattern.

Expect shades to vary between the strips and grains to flow in different directions.

Controlled Random Matching

As random matching, but carefully selected so different shades and grain direction are more harmonised.

Mismatching

A planking effect is deliberately created by using veneers from different logs. More consistent in colour and grain flow than random matching.

Book & Turn Matching

Slip & Turn Matching

Quarter Matching

Random Matching

Controlled Random Matching

Mismatching

As book matching, but alternate leaves are turned so the grain is in the opposite direction.

As slip matching, but alternate leaves are turned so the grain is in the opposite direction.

Four veneer strips are book matched from side to side and top to bottom. Used for creating larger veneer panels.

Mixes veneers not necessarily from the same log, with some turned to create a random effect on the grain pattern. Expect shades to vary between the strips and grains to flow in different directions.

As random matching, but carefully selected so different shades and grain direction are more harmonised.

A planking effect is deliberately created by using veneers from different logs. More consistent in colour and grain flow than random matching.

Book & Turn Matching

Slip & Turn Matching

Quarter Matching

Random Matching

Controlled Random Matching

Mismatching

As book matching, but alternate leaves are turned so the grain is in the opposite direction.

As slip matching, but alternate leaves are turned so the grain is in the opposite direction.

Four veneer strips are book matched from side to side and top to bottom. Used for creating larger veneer panels.

Mixes veneers not necessarily from the same log, with some turned to create a random effect on the grain pattern. Expect shades to vary between the strips and grains to flow in different directions.

As random matching, but carefully selected so different shades and grain direction are more harmonised.

A planking effect is deliberately created by using veneers from different logs. More consistent in colour and grain flow than random matching.